COESFELD

Coesfeld Materialtest produces and distributes material testing equipment for numerous fields of application and instustrial branches. Focus or our activities lies on chemical and petrochemical industires (plastics, rubber, paint, varnish, glue, oil, lubricants and bitumen) as well as manufacturing industries (structural elements, profiles, windows or packaging) and also the automobile industry.

COESFELD

Mineraloil, Bitumen, Lubricants

Quality control of liquid gas, petrol, grease, lubricants and bitumen lies in focus of the field of application. Most of the mentioned materials are tested with regard to international norms and standards. We offer a wide spectrum in this field ranging from A-Z starting with Abel flashpoint, bending beam to cloud and pour point, flash- or freezingpoint to viscosity.

|

Penetration |

Flammability |

|

Fuel |

Bitumen |

|

Grease |

Others |

COESFELD

Polymer Materials

Plastics, rubber and composites are in great focus of our activities. We offer products for static and dynamic tests, impact testing, measurement of hardness as well as thermic test as heat distortion (HDT) and softening temperature (VICAT) and equipment for raw material tests as granulates. Of course we offer the corresponding accessories and instruments for your specimen preparation.

|

Specimen Preparation

|

HDT and VICAT

|

|

Dynamical

|

Statical

|

|

Impact Strength

|

Abraision and Friction

|

|

Raw Material

|

|

COESFELD

Surfaces, Paint and Coatings

The test equipment of this field empraces physical, electrical and thermical test of powder coating, hartz, paint, lacquer and plastic coating. This includes mechanical tests as abraision and gauge, electrical test as cathodic disponding, resistance, and coating thickness, thermical tests as gel time, film forming temperature, softening, melting point, evaporation and corrosion.

|

Electrical

|

Mechanical

|

|

Thermical

|

Film and Surface

|

COESFELD

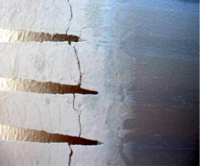

Pipes

Testing of pipes is our field, which is defined most narrow. Most testing equipment relates the the quality control of pipes and pipe coatings according to DIN 30 670. We offer you all that is necessary: Indentation hardness, minimum coating thickness, continuity, coating resistivity, impact strength and heat aging.

|

Indentiation Hardness

|

Minimum Coating Thickness

|

|

Continuity

|

Coating Restistance

|

|

Impact Strength

|

Heat Ageing

|